We have compiled a list of FAQ’s related to PV racking.

Frequently Asked Questions

GENERAL

What are solar mounting systems?

Solar mounting systems are used to fix solar panels onto a variety of surfaces, such as rooftops, wall facades or land. Mounting systems help keep the solar panels or arrays in place and work as the support structure for solar modules.

Mounting systems are generally made from steel or aluminum supports that can hold solar arrays in place through extreme loads from wind, snow and frost.

How are rooftop PV systems mounted?

There are 3 mounting methods for PV systems on commercial building roofs:

- Ballasted Racking

- Uses heavy weights, typically concrete blocks, to anchor PV systems on a flat roof.

- Attached Racking

- Uses roof penetrating anchors to mount PV systems on any type of roof. The number of required penetrations depends on the roof structure, PV system design, and local building codes.

- Hybrid Racking

- Some hybrid systems use a combination of ballast and roof penetrating anchors to fasten the system to the roof.

Can you add solar to all building types?

TerraGen Racking can be installed on most commercial, industrial, warehouse, retail and agricultural facilities. Your roof will be reviewed for suitability prior to finalizing a system plan. We will work with you to design a custom solution that suits your needs

What are the benefits of a rail based system?

There are many benefits of a rail based system:

- Maintain module warranties

- Reduce point loading on your roof by transferring load through continuous base rails

- Reduce electrical materials and installation costs

- Predetermined row spacing and tilt angle

- Install racking and ballast in advance of module placement

The roof consists of both flat and pitched sections, can TerraGen accomodate?

Yes. TerraGen has extensive experience with both flat and pitched roofs. We are able to design different arrays to suit each section of the roof for a complete system that meets your solar needs.

Why should I choose TerraGen for my PV project?

One of the major benefits of TerraGen’s mounting solutions is that we are able to accommodate any layout. This gives solar designers the freedom to create layouts that best fit the project site and their PV system goals.

TECHNICAL

What size of array is best?

Although TerraGen can accommodate any array size, there are a few things to note:

- Square Arrays – the squarer the array, the less ballast required and reduction/elimination of onsite rail cutting

- Limiting Small Sub-Arrays – the smaller the sub-array, the more ballast and components required. Especially in portrait, the number of rows high each module is connected to, will significantly impact the ballast requirements for that module

-

- 5 x 5 produce the best results

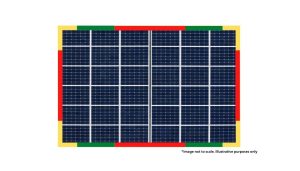

What are clamping zones?

Clamping zones are the sections of the PV module that will be used to clamp the module to the racking using mid and end clamps.

TerraGen racking is designed so that the mid and end clamps fall within the module manufacturers “green” zones. “Green” zones refer to the section of the module where clamping will provide the most stability and best distribution of additional weight, such as snow. Clamping outside of these zones could contribute to accelerated panel degradation and risk of voiding out the module warranty.

What tilt angles can TerraGen accommodate?

Our racking systems are able to accommodate any tilt angle from 0° to 35°.

How is the global loading calculated?

In our Design Package, we provide the global loading which is the weight of the modules, racking and ballast over the footprint area of the array. It does include the interrow spacing, but does not include the building area outside of the array.

Is a wind screen required for TerraGen racking systems?

No. TerraGen has performed wind tunnel testing with no wind screen and therefor it is not needed to reduce the ballast requirements or for structural purposes.

Is TerraGen’s rubber compatible with the roof membrane? Does it maintain warranty?

TerraGen’s TGR system provides rubber pads under the racking to protect the roof membrane from the racking and to allow for drainage.

However, the roof membrane manufacturer and the building owner should be consulted as slip sheets may be required in order for the roof warranty to be maintained.

The roof has drainage slopes that won’t allow for your system to sit flat. What do you recommend?

Drainage slopes are quite common on flat roofs. Our system can handle small undulations and the system will conform to the roof somewhat when the ballast and modules are installed. The rigidity of the base rails also allows to span some minor valleys, if the span is only a couple of ft long or is located under an interrow spacing.

In more extreme cases where the gap is more than a couple of inches or where there may be point loading concerns caused by the uneven roof, it’s recommended to insert a rigid material to act as a shim in the appropriate locations